A premier custom stainless steel fabricator solving complex challenges since 1951. We are a one-stop-shop offering advanced laser cutting (flat, tube, 5-axis), precision forming, and certified welding (GTAW, laser, robotic). We are ISO 9001:2015 certified and experts in stainless steel, duplex, and high-nickel alloys like Hastelloy.

At MET Manufacturing Group, we take pride in our expertise in metal fabrication, where precision, innovation, and craftsmanship come together to create durable and high-quality components. We specialize in transforming raw metal into complex parts and assemblies that serve a wide range of industries, from construction and transportation to energy and manufacturing.

At Kalamazoo Fabricating, we take pride in delivering high-quality metal fabrication solutions that bring precision, strength, and innovation to every project we undertake. We specialize in transforming raw materials into fully engineered components, assemblies, and structures that meet the exacting standards of our customers across diverse industries.

At Anchor Fabrication, we take pride in being a trusted partner for comprehensive metal fabrication solutions that serve a wide range of industries. We bring precision, efficiency, and craftsmanship to every project, combining advanced technology with years of hands-on expertise.

Accurate Metal Fabricating has been providing metal fabrication to OEM's and job shops for over 80 years. We fabricate, engineer, and perforate to the most precise specifications for the most demanding companies. We offer a full range of metal customization and fabrication capabilities that bring your design to reality. Our abilities range from forming and laser-cutting to powder coating and...

At Victory Machine & Fab, we take pride in delivering high-quality metal fabrication solutions that combine precision craftsmanship with advanced technology. We specialize in transforming raw materials into functional, durable, and custom-engineered components that meet the highest industry standards.

More Heavy Fabrication Companies

Metal fabrication processes involve cutting, bending, joining and assembly of metal products. Indoor heavy fabrication facilities can be several stories tall with thousands of square feet of floor space. Some heavy fabrication operations produce large enough products that they are conducted outdoors.

The processes by which structural building materials, airframes, ship hulls and other large materials are produced are considered to be heavy fabrication processes. Other fabricated metal products like furniture, cabinetry, gratings, hand tools, firearms, electronics and other smaller products are considered to be light fabrications.

Heavy fabrications form the backbones of many structures and infrastructure utilities like bridges and tunnels. Steel reinforcement of buildings has become common in all kinds of construction projects. The components required in such applications are often very large, and heavy fabrication facilities must be large and open enough to accommodate them.

The industries that make the most use of heavy fabrication services include the engineering, heavy machinery, petrochemical extraction and refinement, manufacturing, defense contracting and aerospace manufacturing industries. Many heavy fabrication companies supplement their manufacturing services with design consultation and post-processing inspection.

Heavy fabrication companies must offer their customers a range of fabrication services. Fabrication companies compete with each other to offer customers the highest level of efficiency for the lowest price. Innovation is an expression of competitive competition, and innovations in heavy fabrication have streamlined many manufacturing processes.

Robotic welding, for example, has allowed for increased output and more uniform production for many large scale automotive manufacturing operations. Reducing labor intensity and product development saves fabrication companies time and money, and customers often realize the benefits of those savings as well. Metal joining methods like welding and fastening must both be present on a heavy fabrication company's list of capabilities.

Many of the products of heavy fabrication processes end up contributing to the safety of large groups of people. Load bearing elements in bridges, buildings and in other structures must meet strict standards of durability, corrosion resistance and other safeguards. Heavy fabrication companies have a unique responsibility for ensuring the quality of their products for this reason.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

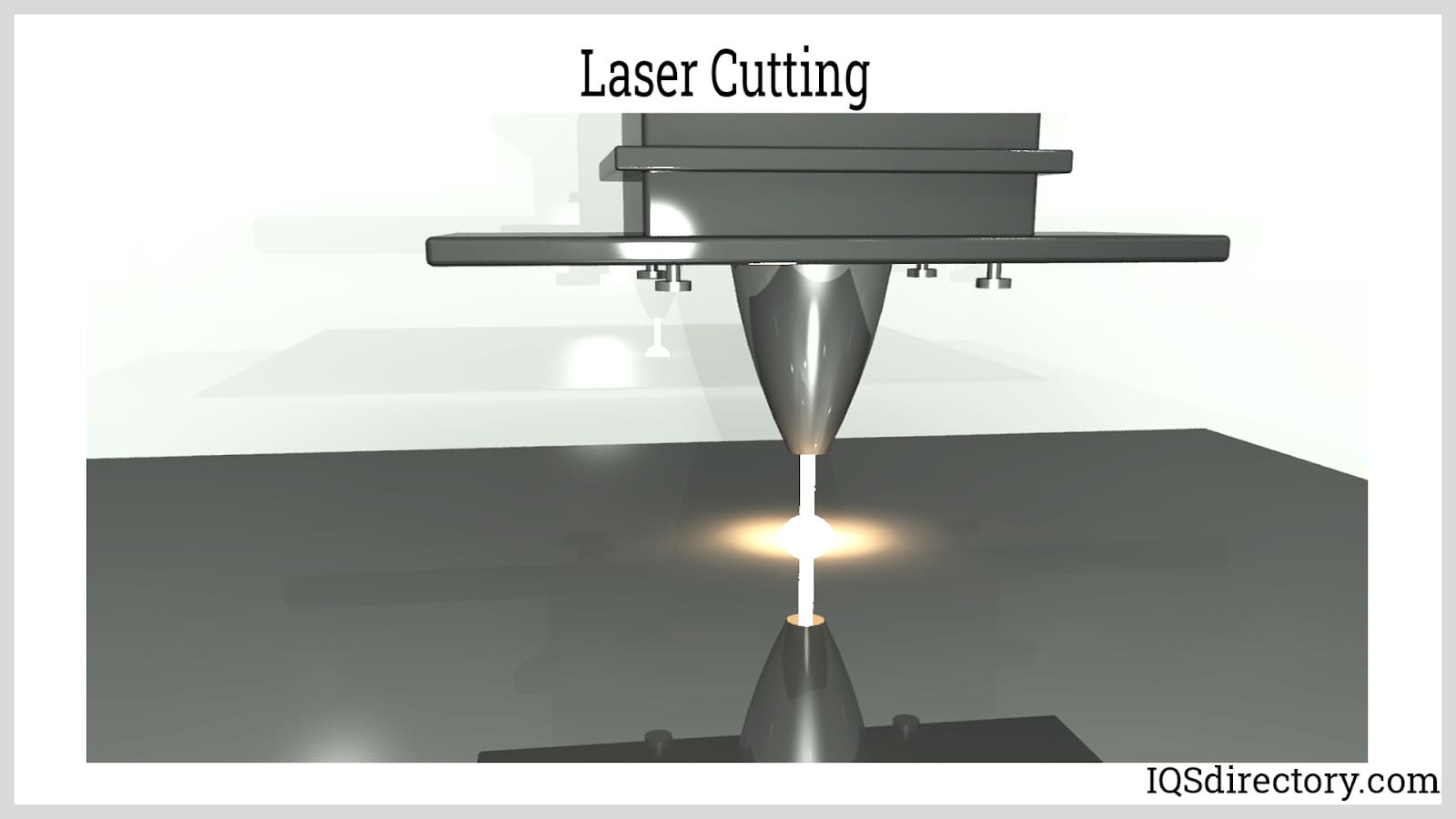

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services