Full service, high volume sheet metal fabrication for OEM’s has occurred for over 8 decades at Accurate Metal Fabricating. Capabilities include light gauge metal fabricating in all forms of steel, aluminum, , stainless steel fabrication, metal welding, & more. Fabricating products for many industries such as power generation, food processing, cabinets, enclosures, P.O.P displays,...

More Metal Forming Companies

Metal forming, or metal shaping, is one of the most basic kinds of metal processing, and yet shaped metal products are involved in a vast amount of products used by people around the world. Shaped gold rings are used as a symbol of marriage, and gold often plays an important role in making symbols appear on the screens of consumer electronics.

In both cases, a metal forming process must be applied to the gold in order to make it usable. Beginning several thousand years ago (and on an industrial scale little more than one or two hundred years ago) methods of metalworking were developed to make tools, weapons, building materials, toys, jewelry, electronics, furniture, transportation equipment and many other utilities for life and leisure. Each fabrication process accommodates different kinds of metals and makes different kinds of shapes.

There are two main categories of metal fabrication. The first, heavy fabrication, involves the production of metal products for use in large applications. Fabricated metal products for use in bridge construction, ship building, aerospace vessel design and other large-scale applications all belong to this category.

All other fabricated metal products for use in smaller-scale applications belong to the category of light fabrication. Stainless steel kitchenware, metal trim and aluminum grating are all examples of light fabrication. The processes by which both light and heavy fabricated products are created include roll forming, press braking, punching, bending, stamping and many others. Roll forming is among the most common metal shaping processes, and it is used to create all manner of metal shapes.

It is a cold forming process, which means that it can shape metals without the application of extreme heat. Roll forming systems involve a long series of rollers of varying configurations; each roller system in the sequence is positioned in a slightly different way, which gradually bends the metal passing through them. By the time the metal passes through the last set of rollers, it has been bent into its final shape.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

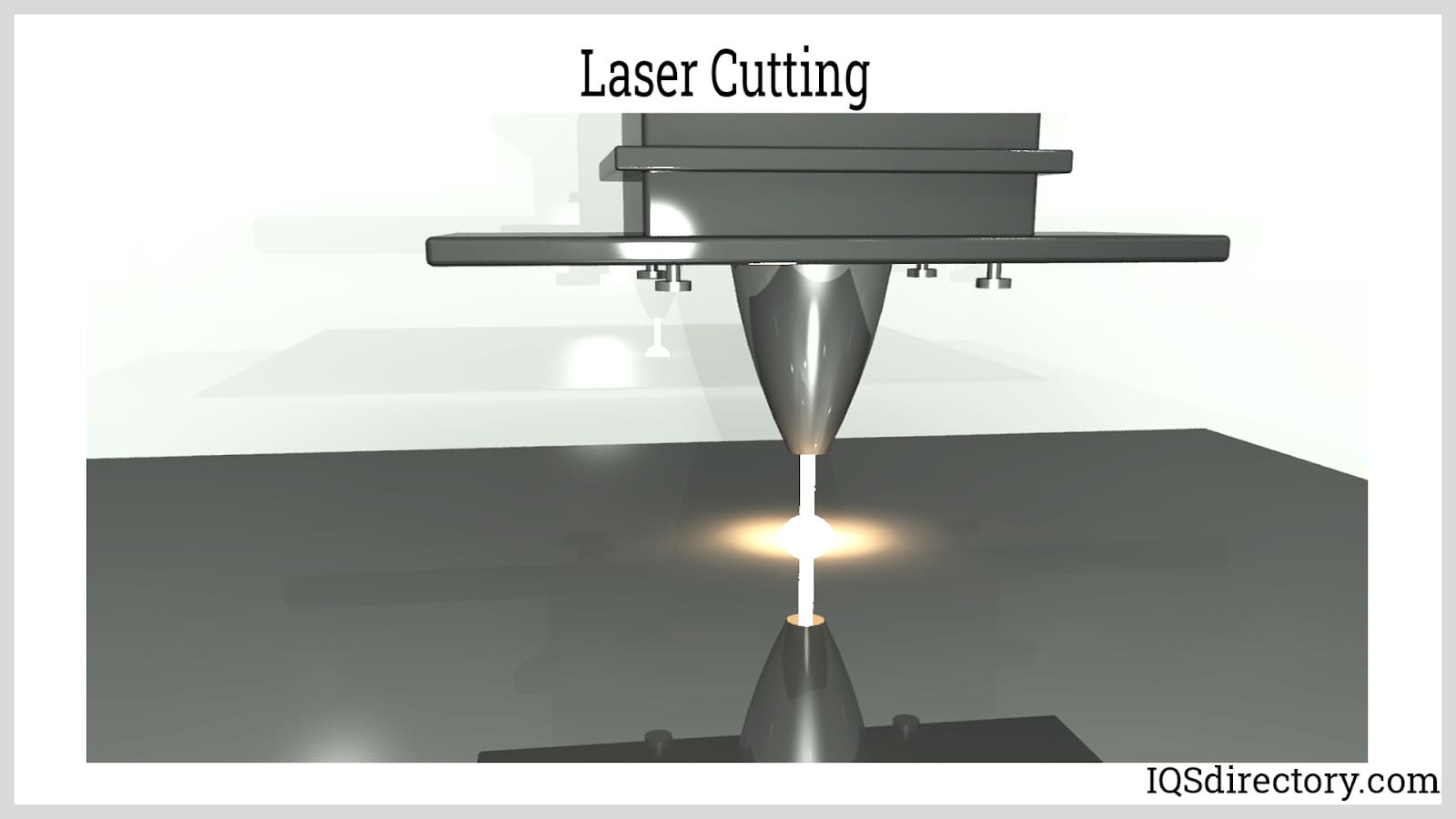

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services