A premier custom stainless steel fabricator solving complex challenges since 1951. We are a one-stop-shop offering advanced laser cutting (flat, tube, 5-axis), precision forming, and certified welding (GTAW, laser, robotic). We are ISO 9001:2015 certified and experts in stainless steel, duplex, and high-nickel alloys like Hastelloy.

At MET Manufacturing Group, we take pride in our expertise in metal fabrication, where precision, innovation, and craftsmanship come together to create durable and high-quality components. We specialize in transforming raw metal into complex parts and assemblies that serve a wide range of industries, from construction and transportation to energy and manufacturing.

At Kalamazoo Fabricating, we take pride in delivering high-quality metal fabrication solutions that bring precision, strength, and innovation to every project we undertake. We specialize in transforming raw materials into fully engineered components, assemblies, and structures that meet the exacting standards of our customers across diverse industries.

At Anchor Fabrication, we take pride in being a trusted partner for comprehensive metal fabrication solutions that serve a wide range of industries. We bring precision, efficiency, and craftsmanship to every project, combining advanced technology with years of hands-on expertise.

Accurate Metal Fabricating has been providing metal fabrication to OEM's and job shops for over 80 years. We fabricate, engineer, and perforate to the most precise specifications for the most demanding companies. We offer a full range of metal customization and fabrication capabilities that bring your design to reality. Our abilities range from forming and laser-cutting to powder coating and...

At Victory Machine & Fab, we take pride in delivering high-quality metal fabrication solutions that combine precision craftsmanship with advanced technology. We specialize in transforming raw materials into functional, durable, and custom-engineered components that meet the highest industry standards.

More Steel Fabricator Companies

Steel Fabricators: Comprehensive Guide to Services, Applications, and Industry Insights

Steel fabricators are skilled professionals who design, engineer, and construct structures and components using steel and other metals. As crucial contributors to the construction, manufacturing, and industrial sectors, steel fabrication specialists use their expertise to transform raw steel into functional and aesthetic elements for a wide range of projects. In this guide, we will cover everything about steel fabricators, from the objects they work on, tools and fabrication techniques, industry applications, buyer considerations, and how to choose the right steel fabricator for your needs. By the end, you’ll have a deep understanding of the steel fabrication industry and the value it brings to countless sectors.

What Do Steel Fabricators Do? Core Responsibilities and Services

Steel fabrication is the process of converting raw steel materials into pre-designed shapes and structures through cutting, bending, welding, and assembling. Professional steel fabricators offer a range of structural and custom metal fabrication services, including:

- Structural steel fabrication for buildings, bridges, and commercial facilities

- Custom metalwork such as staircases, railings, gates, and decorative features

- Heavy steel fabrication for industrial applications and infrastructure projects

- Sheet metal fabrication for ductwork, panels, and enclosures

- Precision fabrication for machinery, equipment, and OEM parts

- Assembly and installation at construction and project sites

Steel fabricators also provide value-added services such as CAD design, project management, prototyping, finishing (painting, powder coating, galvanizing), quality control, and project logistics. Whether working on a single custom component or a large, complex structure, steel fabricators play a pivotal role in ensuring project success, structural integrity, and safety.

Objects and Structures Steel Fabricators Work On

Steel fabricators are typically commissioned to work on an extensive array of steel structures and fabricated metal components across different industries. Common projects include:

- Commercial and Industrial Buildings: Steel frameworks, support beams, columns, and trusses for office buildings, warehouses, and factories.

- Infrastructure Projects: Fabricated steel for bridges, stadiums, airports, power plants, and transportation hubs.

- Residential Projects: Custom staircases, metal railings, steel fences, driveway gates, and ornamental metalwork for homes and apartments.

- Custom Architectural Features: Canopies, awnings, curtain walls, and decorative facades.

- Specialized Equipment: Platforms, mezzanines, catwalks, tanks, silos, conveyors, and frames used in manufacturing and processing plants.

- Agricultural Structures: Steel barns, grain silos, livestock enclosures, and greenhouses.

- Transportation Components: Fabricated steel for railways, bridges, marine docks, and highway structures.

- Renewable Energy: Steel towers and frameworks for wind turbines and solar panel installations.

Are you looking for a steel fabricator for a specific project type? Browse our directory of steel fabrication specialists by application or industry to find the best fit for your needs.

Steel Fabrication Tools, Technologies, and Techniques

Modern steel fabricators utilize a broad assortment of advanced tools, fabrication technologies, and metalworking techniques to achieve precision and efficiency in every project. Key equipment and processes include:

Cutting Tools and Techniques

- Plasma Cutting: High-precision thermal cutting using a plasma torch for complex shapes and thick steel plates.

- Oxy-Acetylene Cutting: Traditional torch cutting for heavy-duty fabrication and demolition.

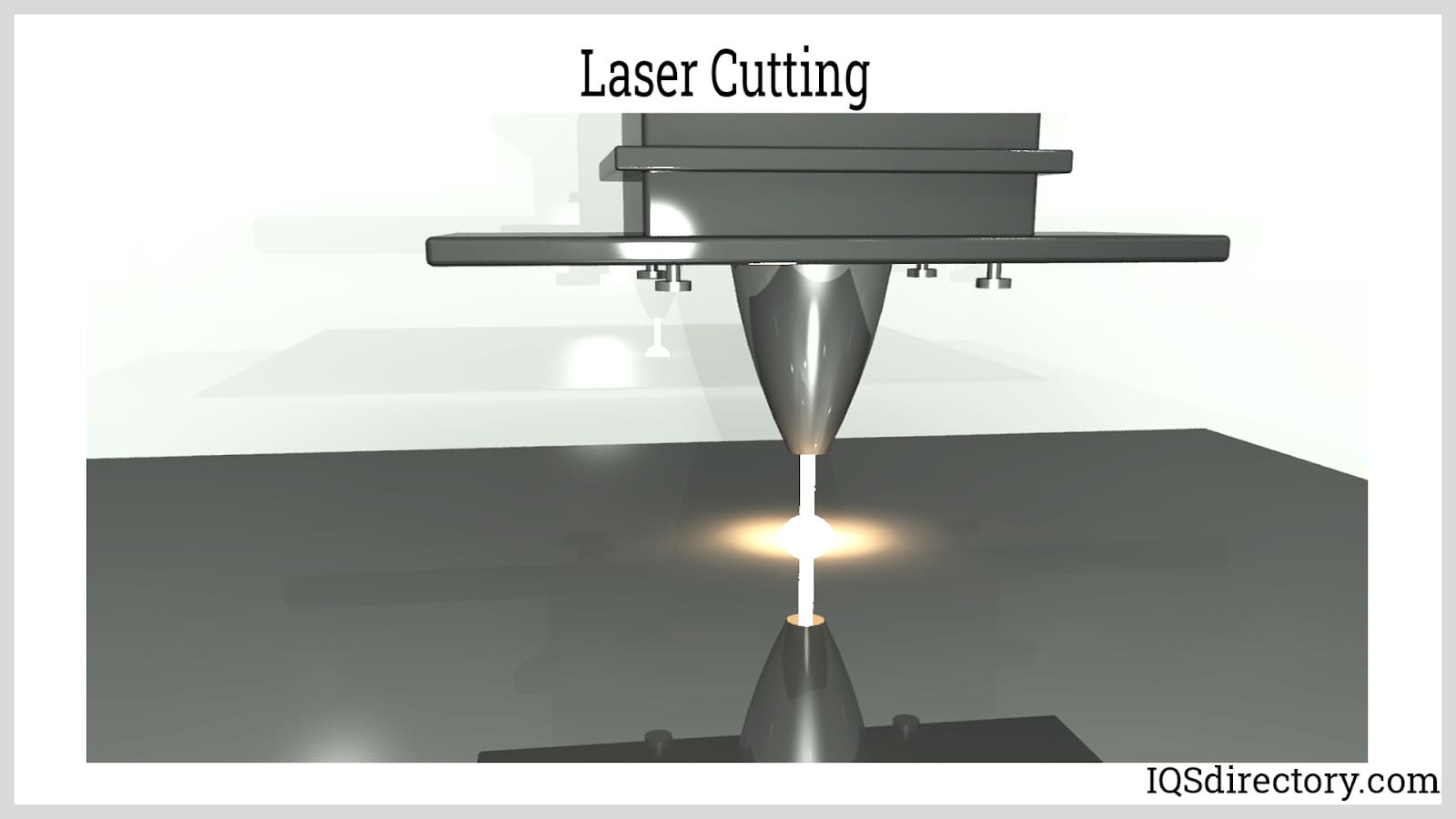

- Laser Cutting: CNC-controlled lasers for intricate, high-accuracy cuts in sheet metal fabrication.

- Mechanical Shears: For straight-line cutting of steel sheets, plates, and bars.

- Waterjet Cutting: Abrasive waterjet systems for heat-free, versatile steel cutting.

Welding Processes

- MIG Welding (Gas Metal Arc Welding): Efficient and versatile for joining various steel grades.

- TIG Welding (Gas Tungsten Arc Welding): Delivers precise, clean welds for specialty and ornamental steelwork.

- Arc Welding (Stick Welding): Reliable for heavy-gauge steel and outdoor fabrication jobs.

- Robotic Welding: Automated welding systems for high-volume and repetitive assembly tasks.

Bending and Forming Equipment

- Press Brakes: Hydraulic or CNC brakes for bending steel sheets and plates to custom angles.

- Rollers: For producing curved steel components such as arches and cylinders.

- Tubing Benders: Used to form steel pipes and tubing for railings, frames, and supports.

Computer-Aided Design (CAD) and Drafting

Steel fabricators rely heavily on advanced CAD software (such as AutoCAD, SolidWorks, or Tekla Structures) to create 2D and 3D models, ensuring that every component meets precise design specifications before manufacturing begins. CAD design also enables better visualization, cost estimation, and error reduction during fabrication.

Lifting, Handling, and Rigging Equipment

- Cranes, Hoists, and Forklifts: Essential for moving heavy steel beams, columns, and assemblies safely around the shop or jobsite.

- Rigging Hardware: Slings, chains, and shackles used for precise placement of structural steel.

Finishing and Surface Treatment Tools

- Grinders and Sanders: For smoothing welds and preparing surfaces for painting or coating.

- Shot Blasting Equipment: Used to clean and prepare steel for finishing processes such as galvanizing or powder coating.

- Painting and Coating Booths: For corrosion protection and aesthetic finishes.

Curious about which fabrication process is best for your project? Ask our experts or request a quote for tailored solutions and process recommendations.

Employment, Training, and Certification in Steel Fabrication

The steel fabrication industry offers a diverse range of career paths for skilled tradespeople, engineers, and project managers. Steel fabricators can be employed full-time, part-time, or on a contractual basis in manufacturing plants, fabrication shops, construction firms, and even as independent contractors. Many successful steel fabricators go on to run their own metal fabrication businesses, serving both local and national clients.

How to Become a Steel Fabricator

- Technical Training: Many fabricators begin by attending technical schools or vocational programs specializing in welding, metal fabrication, or mechanical engineering.

- Apprenticeships: On-the-job training under experienced steel fabricators is a common pathway to mastering fabrication skills and learning industry standards.

- Certifications: Professional certifications (such as AWS Certified Welder, CWI, or ASME certifications) enhance credibility and employability in the field.

- College Degrees: Some roles, especially in project management or engineering, may require an associate’s or bachelor’s degree in related disciplines.

For those interested in pursuing a career in metal fabrication, the demand for skilled fabricators continues to grow thanks to ongoing construction, infrastructure upgrades, and advancements in manufacturing technology.

Key Considerations When Hiring a Steel Fabricator

Choosing the right steel fabrication partner is critical to the success of any construction, manufacturing, or industrial project. Here are essential factors to evaluate during your selection process:

Experience and Technical Expertise

Select a steel fabricator with extensive experience in projects similar to yours. Review their past work, industry certifications, and technical capabilities. Ask for a portfolio of completed projects to gauge their proficiency in your desired application—whether structural steel, custom metalwork, or heavy fabrication.

Production Capacity and Equipment

Evaluate whether the steel fabricator’s facilities, machinery, and workforce can handle your project’s scale, complexity, and timeline. Leading steel fabricators invest in state-of-the-art equipment for cutting, welding, and assembly, ensuring higher quality and faster turnaround times.

Quality Control and Industry Standards

Ensure the steel fabricator adheres to rigorous quality assurance processes, such as ISO 9001 or AISC certification. Ask about their inspection procedures, material traceability, and how they manage compliance with local building codes and safety regulations.

Communication and Project Management

Effective communication and transparent project management are vital for keeping your project on track. Choose a fabricator who provides regular updates, clear documentation, and direct points of contact from design through delivery.

Cost, Lead Times, and Flexibility

Solicit detailed quotes from multiple steel fabricators to compare pricing, payment terms, and delivery schedules. Consider the value of shorter lead times, in-house design services, and the ability to accommodate last-minute changes without sacrificing quality.

References and Reputation

Research customer testimonials, case studies, and online reviews to verify the fabricator’s reputation for quality workmanship, reliability, and customer service. Reputable steel fabricators will gladly provide references upon request.

Need help comparing steel fabricators? Use our RFQ form to get competitive quotes from qualified providers in your area.

Benefits of Hiring Professional Steel Fabricators

Partnering with an experienced steel fabricator offers a host of advantages for your project:

- Expert Craftsmanship: Skilled fabricators deliver precise, structurally sound components that meet or exceed project specifications.

- Customization: Tailored solutions for unique or complex architectural and industrial requirements.

- Efficiency and Speed: Advanced equipment and streamlined workflows reduce turnaround times and minimize project delays.

- Cost Savings: Optimized fabrication processes and material utilization lower overall project costs.

- Quality Assurance: Adherence to industry standards and inspection protocols ensures safety and performance.

- Versatility: Capable of delivering solutions for construction, manufacturing, energy, transportation, and more.

- End-to-End Service: From CAD design and prototyping through fabrication, finishing, and installation.

Industry Applications for Steel Fabricators

Steel fabricators are essential to numerous industries. Common applications include:

Construction and Building

From skyscrapers and warehouses to stadiums and hospitals, structural steel fabrication forms the backbone of modern construction. Fabricators work closely with architects, engineers, and contractors to deliver safe, sustainable, and cost-effective building solutions.

Manufacturing and Industrial Equipment

Steel fabricators design and build machinery frames, conveyor systems, production line supports, and OEM parts for manufacturers. Precision fabrication ensures optimal performance and long service life for critical equipment.

Infrastructure and Civil Engineering

Fabricated steel is key to infrastructure projects such as bridges, overpasses, tunnels, water treatment plants, and transportation facilities. Fabricators help deliver durable, corrosion-resistant, and low-maintenance structures.

Agriculture and Food Processing

In agriculture, steel fabricators supply barns, grain silos, animal enclosures, and specialized equipment for food processing plants. Their work supports increased capacity, safety, and biosecurity for agricultural operations.

Energy and Utilities

Steel fabrication is vital to oil and gas, power generation, wind energy, and renewable energy projects. Applications include pipelines, transmission towers, substation structures, and wind turbine supports.

Transportation and Logistics

Fabricators provide steel bridge components, railway supports, marine infrastructure, and heavy-duty racks for logistics and freight operations.

Wondering how steel fabrication can add value to your industry? Contact our specialists for industry-specific guidance and solutions.

How to Choose the Best Steel Fabricator for Your Project

Finding the right steel fabricator is a decision that can impact the safety, quality, and overall success of your project. Follow these steps to make an informed choice:

- Define Your Project Requirements: Clarify the scope, materials, tolerances, certifications, and delivery deadlines for your project.

- Research Qualified Fabricators: Use our steel fabricator directory to identify businesses with relevant expertise and capabilities.

- Review Portfolios and References: Examine completed projects, customer testimonials, and industry accreditations.

- Request Detailed Quotes: Submit RFQs to multiple fabricators, specifying your exact needs for accurate comparisons.

- Evaluate Communication and Support: Assess responsiveness, willingness to answer technical questions, and project management processes.

- Visit Facilities (if possible): In-person visits can help you assess equipment, safety practices, and quality control firsthand.

- Negotiate Terms and Finalize Agreements: Ensure you have clear contracts covering scope, pricing, timelines, and warranties.

Use our directory to compare steel fabricators by location, specialization, and customer reviews for the best results.

Frequently Asked Questions About Steel Fabricators

What is the difference between metal fabrication and steel fabrication?

Metal fabrication refers to the process of cutting, shaping, and assembling any type of metal, including aluminum, stainless steel, copper, and more. Steel fabrication specifically focuses on creating products and structures from carbon steel, stainless steel, and alloy steels. Steel fabrication is favored for its strength, durability, and versatility in construction and industrial uses.

How do I get a quote for steel fabrication services?

Gather your project details—including drawings, specifications, materials, and timelines—then use our RFQ form to submit your request to multiple steel fabricators. This approach saves time and ensures competitive pricing from qualified providers.

What certifications should a steel fabricator have?

Look for steel fabricators with certifications such as AWS Certified Welder, AISC (American Institute of Steel Construction), ISO 9001, and ASME. These demonstrate commitment to quality standards and regulatory compliance.

Can steel fabricators assist with design and engineering?

Yes, many steel fabricators offer in-house engineering and CAD design services. This ensures your project is optimized for manufacturability, cost-efficiency, and compliance with building codes.

What are the lead times for custom steel fabrication?

Lead times vary based on project complexity, size, and fabricator workload. Simple projects may take a few days, while large or highly customized structures could require several weeks. Early engagement and clear communication help minimize delays.

What industries rely most on steel fabrication?

Key industries include construction, manufacturing, infrastructure, energy, agriculture, transportation, and utilities. Steel fabrication underpins everything from skyscrapers and bridges to machinery and renewable energy systems.

Ready to Start Your Steel Fabrication Project?

With the right steel fabricator, you gain a partner who can turn your vision into durable, high-performance structures and components. Whether you’re seeking structural steel contractors, custom metal fabricators, or specialized fabrication services, our directory makes it easy to compare providers, request quotes, and connect with industry leaders.

- Search by location or specialization to find steel fabricators near you

- Review business profiles and project portfolios to assess fit

- Use our RFQ form to contact multiple providers with one inquiry

Start your search today and discover the benefits of partnering with top-rated steel fabrication experts. Find a steel fabricator now or request a custom quote for your next project.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services