A premier custom stainless steel fabricator solving complex challenges since 1951. We are a one-stop-shop offering advanced laser cutting (flat, tube, 5-axis), precision forming, and certified welding (GTAW, laser, robotic). We are ISO 9001:2015 certified and experts in stainless steel, duplex, and high-nickel alloys like Hastelloy.

At MET Manufacturing Group, we take pride in our expertise in metal fabrication, where precision, innovation, and craftsmanship come together to create durable and high-quality components. We specialize in transforming raw metal into complex parts and assemblies that serve a wide range of industries, from construction and transportation to energy and manufacturing.

At Kalamazoo Fabricating, we take pride in delivering high-quality metal fabrication solutions that bring precision, strength, and innovation to every project we undertake. We specialize in transforming raw materials into fully engineered components, assemblies, and structures that meet the exacting standards of our customers across diverse industries.

At Anchor Fabrication, we take pride in being a trusted partner for comprehensive metal fabrication solutions that serve a wide range of industries. We bring precision, efficiency, and craftsmanship to every project, combining advanced technology with years of hands-on expertise.

Accurate Metal Fabricating has been providing metal fabrication to OEM's and job shops for over 80 years. We fabricate, engineer, and perforate to the most precise specifications for the most demanding companies. We offer a full range of metal customization and fabrication capabilities that bring your design to reality. Our abilities range from forming and laser-cutting to powder coating and...

At Victory Machine & Fab, we take pride in delivering high-quality metal fabrication solutions that combine precision craftsmanship with advanced technology. We specialize in transforming raw materials into functional, durable, and custom-engineered components that meet the highest industry standards.

More Stainless Steel Fabricator Companies

Comprehensive Guide to Stainless Steel Fabrication

Stainless steel fabrication is a highly specialized process that involves shaping, cutting, and transforming stainless steel materials into a wide range of products and structural components. From tanks and piping systems to industrial equipment and intricate machinery parts, stainless steel fabrication supports many of the world’s most demanding industries. Stainless steel is a preferred choice for fabricators because of its exceptional durability, outstanding resistance to corrosion, and modern aesthetic appeal, making it vital for applications where hygiene, strength, and longevity are paramount.

Are you researching stainless steel fabrication services for your next project? Do you need to compare stainless steel fabricators or understand what sets leading fabrication companies apart? This guide walks you through the key aspects of stainless steel fabrication, including fabrication techniques, industry applications, quality standards, and tips for choosing a reputable fabricator for your unique needs.

What Do Stainless Steel Fabricators Do?

Stainless steel fabricators are skilled professionals and technicians who specialize in transforming raw stainless steel material into functional, durable, and visually appealing products. They use a variety of metalworking techniques and advanced equipment to fabricate, shape, cut, and weld stainless steel components and assemblies. Fabricators may work with different types and grades of stainless steel, including austenitic, ferritic, and duplex stainless steels, each chosen to fit specific project requirements.

Typical tasks performed by stainless steel fabrication companies include:

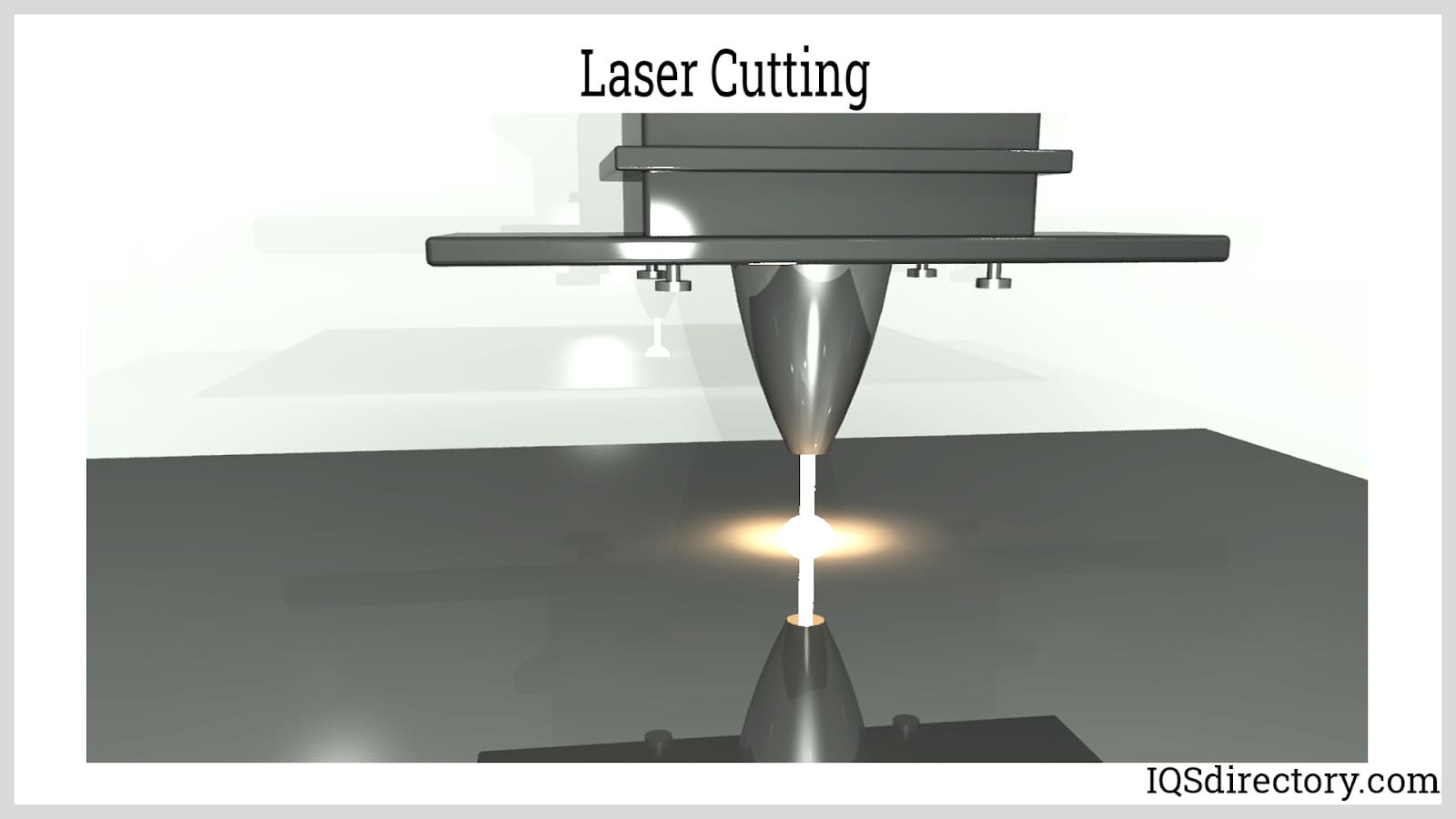

- Precision cutting (laser cutting, plasma cutting, waterjet cutting, and shearing)

- Bending, folding, and rolling stainless steel sheets and plates

- Welding and joining stainless steel parts using TIG, MIG, or spot welding techniques

- Machining, drilling, and tapping for custom parts and components

- Surface finishing processes such as polishing, passivating, bead blasting, and electroplating

- Assembly and integration of subcomponents for turnkey solutions

- Custom fabrication to meet unique customer designs and specifications

Looking for custom stainless steel fabrication? Ask questions like: What fabrication methods does your shop offer? Can you handle both prototyping and large production runs? Understanding the capabilities of each fabricator is key to the success of your project.

How Are Stainless Steel Fabricators Employed?

Stainless steel fabricators are employed across a wide array of industries. They may work for large manufacturing companies, specialized fabrication shops, small businesses, or as independent contractors. Some operate in niche markets focusing on one sector, while others offer comprehensive fabrication services for multiple industries and end-use applications. Their expertise is essential for delivering high-performance stainless steel products that meet stringent industry requirements.

Industries and Applications Supported by Stainless Steel Fabrication

Construction

Stainless steel plays a critical role in the construction industry due to its durability, corrosion resistance, and attractive finish. Fabricators supply components such as handrails, balustrades, architectural cladding, canopies, and structural supports (beams, columns, trusses). Stainless steel is ideal for both interior and exterior applications, offering longevity and reduced maintenance costs for commercial, industrial, and residential buildings.

Food Processing

In the food processing industry, stainless steel is the gold standard for equipment exposed to moisture, heat, and rigorous cleaning. Fabricators supply items such as mixing tanks, conveyor systems, work surfaces, storage silos, and pipework. Stainless steel’s non-porous surface prevents bacteria buildup, making it a hygienic choice for food-safe fabrication, bakery equipment, breweries, and dairy plants.

Medical Equipment

Medical device manufacturers rely on stainless steel fabricators to produce components that demand the highest standards of cleanliness and precision. Fabricators supply parts for surgical tools, dental instruments, diagnostic equipment, hospital furniture, sterilization trays, and laboratory fixtures. The non-reactive, sterilizable nature of stainless steel makes it essential in healthcare environments.

Automotive

The automotive industry utilizes stainless steel for its strength, corrosion resistance, and ability to withstand high temperatures. Fabricators manufacture exhaust systems, fuel tanks, catalytic converter housings, chassis components, trim, and heat shields. Stainless steel ensures automotive components last longer and perform reliably under harsh conditions.

Aerospace

Stainless steel’s high strength-to-weight ratio and resistance to extreme temperatures make it invaluable in the aerospace industry. Fabricators produce critical parts such as jet engine components, airframe supports, fuel tanks, brackets, fasteners, and landing gear elements. Aerospace fabrication demands tight tolerances and rigorous quality control.

Marine

Saltwater exposure is no match for stainless steel, making it the material of choice in the marine industry. Fabricators produce propellers, anchors, deck fittings, marine hardware, ladders, rails, and hull reinforcements. Marine-grade stainless steel resists pitting, rust, and corrosion, ensuring the longevity of vessels and offshore structures.

Consumer Products

Stainless steel is a staple in consumer goods due to its clean look and toughness. Fabricators supply handles, frames, furniture, appliances, sinks, kitchenware, and decorative accents. High-end, modern kitchens and outdoor living spaces often feature custom-fabricated stainless steel products.

Oil & Gas, Chemical, and Pharmaceutical Industries

Across the oil and gas, chemical processing, and pharmaceutical sectors, stainless steel fabrication is crucial for creating pressure vessels, storage tanks, pipework, heat exchangers, and filtration systems. The ability to withstand corrosive substances, fluctuating pressures, and temperature extremes makes stainless steel indispensable for these demanding environments.

Renewable Energy and Power Generation

Stainless steel fabricators contribute components for wind turbines, solar panel frames, hydroelectric equipment, and energy storage systems. The material’s durability and resistance to environmental degradation ensure reliable, long-term performance in renewable energy applications.

Curious about specific fabrication projects in your industry? Try search phrases like: “custom stainless steel fabrication for food processing plants” or “marine-grade stainless steel fabricators near me” to find specialists in your required field.

Considerations When Hiring Stainless Steel Fabricators

Choosing a stainless steel fabrication company is a significant decision that impacts product quality, compliance, and project timelines. Here are key factors to consider when evaluating fabrication partners:

Quality Control and Certification

Not all fabricators operate at the same level of quality. Look for companies that adhere to recognized standards (such as ISO 9001 or ASME), maintain traceability of materials, and provide detailed inspection reports. Certifications from organizations like the American Welding Society (AWS) or the Specialty Steel Industry of North America (SSINA) indicate a commitment to excellence.

Experience and Technical Expertise

Experience matters. A fabricator with a proven track record in your industry is more likely to understand your requirements, regulatory standards, and application challenges. Assess their portfolio: Have they completed similar projects? Can they recommend cost-saving design improvements?

Advanced Technology and Equipment

Top stainless steel fabricators invest in modern tools such as CNC laser cutters, automated welding systems, and 3D modeling software. Advanced capabilities enable greater precision, repeatability, and efficiency—key for complex or high-volume projects.

Safety and Compliance

Fabricating stainless steel can involve hazardous processes. Ensure fabricators comply with safety regulations (such as OSHA standards), maintain robust safety protocols, and equip their teams with appropriate personal protective equipment (PPE).

Environmental Responsibility

Responsible fabricators minimize waste, recycle scrap, and implement pollution controls. Ask about their environmental policies and certifications (such as ISO 14001) to ensure your project has a minimal environmental footprint.

Ethical Labor Practices

Choose fabricators who are transparent about their labor practices, use fair employment policies, and demonstrate social responsibility. Certifications or memberships in ethical trade organizations can provide additional assurance.

Wondering how to vet a stainless steel fabrication company? Consider asking: What quality certifications do you hold? Can you provide case studies or references for similar projects? How do you ensure safety and environmental compliance?

Key Organizations Governing Stainless Steel Fabricators

Several organizations set guidelines, standards, and certifications to ensure safe and effective stainless steel fabrication in the United States and globally. These bodies promote best practices, education, and continuous improvement throughout the industry:

Occupational Safety and Health Administration (OSHA)

OSHA establishes and enforces workplace safety standards, including requirements for metal fabrication shops. Their guidelines help protect workers from hazards associated with welding, cutting, and handling stainless steel materials.

American Welding Society (AWS)

The AWS develops codes, standards, and certifications for welding and fabrication. Credentials such as Certified Welder (CW) and Certified Welding Inspector (CWI) demonstrate a high level of skill and adherence to industry best practices.

Specialty Steel Industry of North America (SSINA)

SSINA represents stainless steel producers, distributors, and fabricators, offering guidance, technical resources, and the Certified Stainless Steel Fabricator (CSSF) program. This voluntary certification recognizes fabricators who demonstrate expertise and quality in stainless steel fabrication.

International Stainless Steel Forum (ISSF)

The ISSF is a global association advancing the interests of the stainless steel industry. It develops standards, shares technical knowledge, and promotes sustainable fabrication practices worldwide.

Additional Standards and Certifications

- ISO 9001 – Quality management systems for manufacturing and fabrication

- ISO 14001 – Environmental management systems

- ASME (American Society of Mechanical Engineers) – Pressure vessel and piping codes

- ASTM International – Material and testing standards for stainless steel alloys

Need help understanding which certifications matter for your application? Search for: “required certifications for stainless steel fabrication in [your industry/region]”.

Benefits of Stainless Steel Fabricators

Partnering with a reputable stainless steel fabrication company brings a range of benefits, from tailored solutions to operational cost savings. Here’s what you can expect:

Customization and Flexibility

Custom stainless steel fabrication allows you to achieve precise specifications, unique shapes, and tailored finishes that off-the-shelf products cannot provide. Fabricators can work from your drawings or collaborate in the design phase to optimize manufacturability and performance.

Superior Quality and Consistency

Experienced fabricators source high-grade stainless steel and use advanced inspection methods to guarantee quality and consistency throughout production. The result is products that meet or exceed industry standards for strength, hygiene, and appearance.

Long-Lasting Durability

Stainless steel offers unmatched longevity, resisting rust, corrosion, and physical wear—making it ideal for harsh environments, high-moisture settings, and demanding industrial applications. Well-fabricated stainless steel products provide years of reliable service with minimal maintenance.

Cost-Effectiveness Over Time

While the initial investment in custom stainless steel fabrication may be higher than alternatives, its long service life, low maintenance requirements, and reduced downtime make it a cost-effective solution in the long run. Fabricators often help optimize designs for manufacturability and budget.

Compliance and Peace of Mind

Professional stainless steel fabricators stay current with industry regulations and standards, ensuring your products comply with all relevant codes. This is critical for industries like pharmaceuticals, food processing, and construction, where non-compliance can lead to costly delays or penalties.

Innovation and Added Value

Modern fabricators can offer value-added services such as prototyping, reverse engineering, just-in-time delivery, and integration with supply chain management systems. These capabilities support innovation and streamline your project workflow from concept to installation.

Want to learn more about the ROI of stainless steel fabrication? Try searches like: “lifetime cost comparison of stainless steel vs. other materials” or “benefits of custom stainless steel fabrication for industrial applications”.

Choosing the Right Stainless Steel Fabricator

To ensure the most positive outcome when selecting a stainless steel fabrication partner, it’s essential to conduct thorough research and comparisons. Here’s a step-by-step approach to finding the best fit for your project:

- Use our directory of stainless steel fabricators to compare fabrication companies by location, sector expertise, and capabilities.

- Review each fabricator’s business profile page for details on their experience, certifications, and in-house processes. Look for case studies, project galleries, and client testimonials.

- Visit the fabricator’s website using our patented website previewer to quickly understand their specialties, equipment, and quality systems.

- Contact multiple stainless steel fabricators using our RFQ (Request for Quote) form to receive competitive proposals for your project requirements.

- Ask targeted questions about lead times, technical support, materials sourcing, and after-sales service. Evaluate their responsiveness and willingness to collaborate.

Ready to get started? Search phrases like: “best stainless steel fabricators for commercial kitchen equipment” or “how to select a stainless steel fabrication company” to help guide your research and shortlisting process.

Frequently Asked Questions About Stainless Steel Fabrication

What types of stainless steel do fabricators use?

Fabricators commonly work with austenitic stainless steels (such as 304 and 316 grades), ferritic, martensitic, and duplex stainless steels. The choice of alloy depends on the application, corrosion resistance needs, strength requirements, and budget. Discuss your project needs with the fabricator to determine the best material.

How do I ensure my stainless steel fabrication project meets hygiene standards?

For food, medical, and pharmaceutical applications, request fabrication in compliance with standards such as 3-A Sanitary Standards, FDA guidelines, or GMP (Good Manufacturing Practice). Surface finishing and passivation are critical for hygienic environments—ask your fabricator about their finishing processes.

What is the typical lead time for custom stainless steel fabrication?

Lead times vary depending on project complexity, material availability, and fabricator workload. Simple projects may be completed in days, while complex assemblies can take weeks. Always confirm timelines during the quoting process.

Can stainless steel fabricators provide design assistance?

Many fabricators offer in-house engineering support or work with your design team to optimize manufacturability, reduce costs, and ensure compliance. Early collaboration accelerates timelines and reduces errors.

How do I get a quote for stainless steel fabrication services?

Gather your project drawings, specifications, and quantity requirements. Use our directory or RFQ form to contact multiple fabricators for quotes. Providing detailed information up front ensures accurate pricing and faster responses.

Conclusion: Unlock the Potential of Stainless Steel Fabrication

Stainless steel fabrication is essential to modern industry, enabling the creation of products that are strong, hygienic, and visually appealing. Whether you need a custom solution for a challenging environment or high-volume production of industrial components, partnering with the right stainless steel fabricator ensures your project’s success.

Ready to explore your options? Use our resources to compare leading stainless steel fabricators, review their capabilities, and request quotes—all in one place. For further research, try queries like “custom stainless steel fabrication services near me” or “industrial stainless steel fabricators for medical equipment” to find the perfect partner for your project’s needs.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services