Midland Metal Products

Midland Metal ProductsRequest A Quote

Hammond, IN | 773-927-5700https://www.midlandmetalproducts.com/

At Midland Metal Products, we have built our reputation as a trusted leader in custom metal fabrication by combining decades of experience with a commitment to precision and innovation. We take pride in transforming raw materials into high-quality components and finished products that meet the unique specifications of our clients across a wide range of industries. Our team works with steel, aluminum, and other metals, using advanced cutting, bending, and welding techniques to deliver durable, reliable, and functional solutions. We provide full-service metal fabrication, from initial design consultation and prototyping through to large-scale production and finishing. By investing in state-of-the-art machinery and continually refining our processes, we are able to maintain exceptional accuracy and consistency, even on the most complex projects. Whether it is fabricating intricate parts, assembling large-scale structures, or delivering ready-to-install components, we ensure that every step is guided by strict quality control standards and a dedication to customer satisfaction. Our capabilities extend beyond fabrication, as we also offer engineering support, project management, and finishing services such as powder coating and polishing to provide our clients with complete, ready-to-use solutions. As a family-owned business with deep roots in the industry, we are committed not only to producing exceptional metal products but also to building lasting relationships with our clients. We recognize that our success is tied to the success of those we serve, and we dedicate ourselves to delivering excellence in every project. By combining craftsmanship with cutting-edge technology, we continue to uphold our reputation as a dependable source for high-quality metal fabrication solutions.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

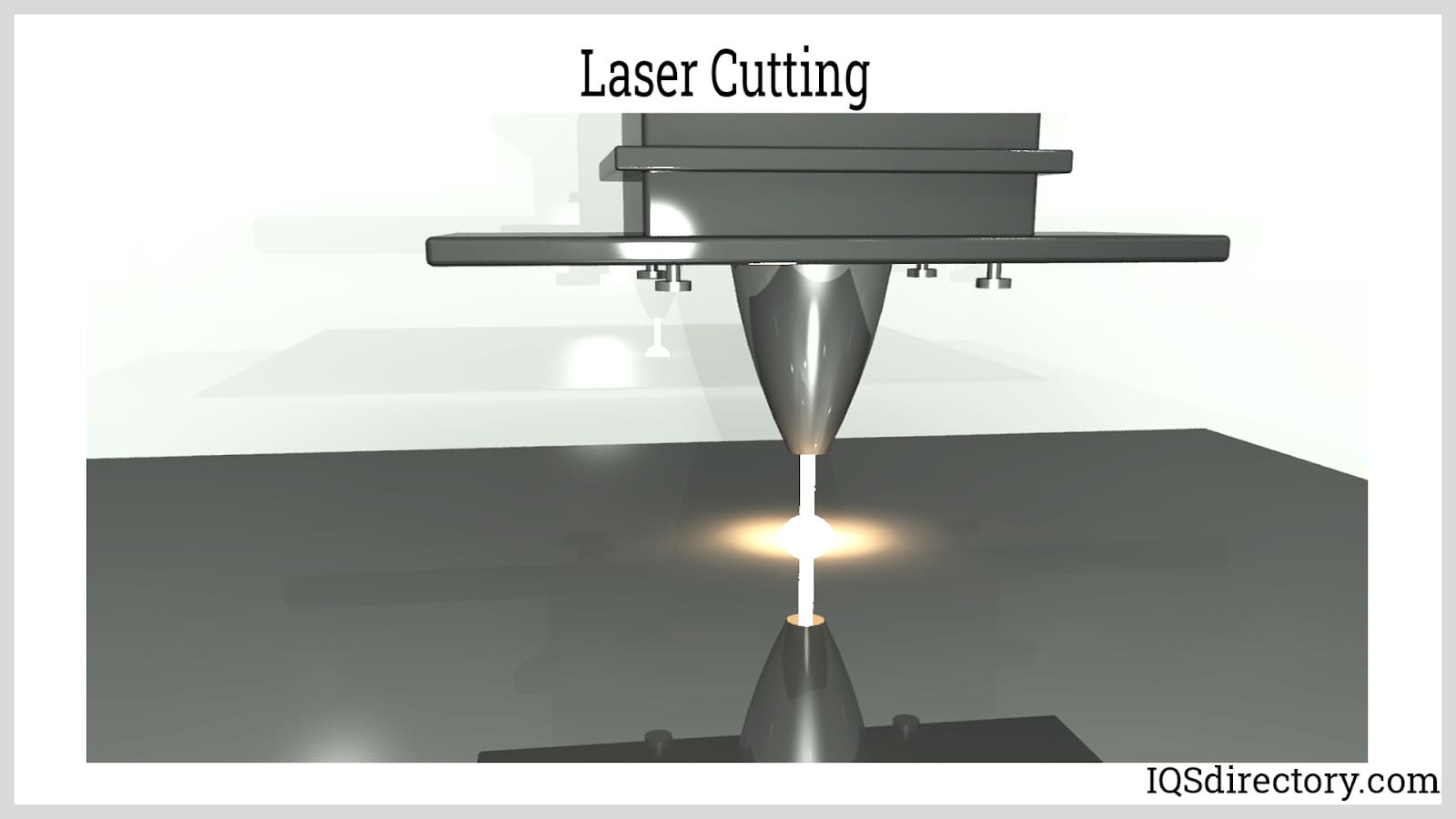

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services