A premier custom stainless steel fabricator solving complex challenges since 1951. We are a one-stop-shop offering advanced laser cutting (flat, tube, 5-axis), precision forming, and certified welding (GTAW, laser, robotic). We are ISO 9001:2015 certified and experts in stainless steel, duplex, and high-nickel alloys like Hastelloy.

At MET Manufacturing Group, we take pride in our expertise in metal fabrication, where precision, innovation, and craftsmanship come together to create durable and high-quality components. We specialize in transforming raw metal into complex parts and assemblies that serve a wide range of industries, from construction and transportation to energy and manufacturing.

At Kalamazoo Fabricating, we take pride in delivering high-quality metal fabrication solutions that bring precision, strength, and innovation to every project we undertake. We specialize in transforming raw materials into fully engineered components, assemblies, and structures that meet the exacting standards of our customers across diverse industries.

At Anchor Fabrication, we take pride in being a trusted partner for comprehensive metal fabrication solutions that serve a wide range of industries. We bring precision, efficiency, and craftsmanship to every project, combining advanced technology with years of hands-on expertise.

Accurate Metal Fabricating has been providing metal fabrication to OEM's and job shops for over 80 years. We fabricate, engineer, and perforate to the most precise specifications for the most demanding companies. We offer a full range of metal customization and fabrication capabilities that bring your design to reality. Our abilities range from forming and laser-cutting to powder coating and...

At Victory Machine & Fab, we take pride in delivering high-quality metal fabrication solutions that combine precision craftsmanship with advanced technology. We specialize in transforming raw materials into functional, durable, and custom-engineered components that meet the highest industry standards.

More Fabricated Metal Product Companies

Fabrication is a blanket term for many metalworking processes; these include rolling, punching, stamping, sintering, welding, machining and many others.

Fabrication is a secondary metalworking process. Primary processes involve forming raw metal materials into shapes; extrusion and molding are both primary processes. Metal fabricators take extrusions and molded metals and weld them together, bend them and cut them to size. Nearly all products of primary metalworking processes require secondary processing to some extent before they become usable.

For example, metal plates don't become hinges until their edges are bent, holes are drilled or punched and pins are inserted to connect them. Bar stock and small metal rods don't become fasteners until they are machined and slotted. Fabrication services are essential to a long list of industrial operations including the automotive, aerospace, marine, construction, engineering, plumbing, petrochemical exploration and development, food and beverage and commercial product industries.

Fabricated metal products are prominent features of most bridges, airplanes, ships and buildings. Smaller metal fabrications are also important parts of water tanks, electrical wiring enclosures, metal cabinets, frames, brackets, panels, outdoor grills and even sculptures.

Fabricated metal products are produced by fabrication processes. These processes range in complexity, expense and labor intensity and can be used to create stock products and custom fabrications. Roll formers, for example, involve long series of rollers in different configurations that are used to bend raw metal into useful products.

Roll forming can be a completely automated process once the rollers have been configured. Roll formers are often managed by advanced computer software that monitors and controls the movement and positioning of the rollers, ensuring the closest possible relationship between product concept and reality.

On the other end of the labor intensity spectrum are processes like press braking, which require the constant attention of trained technicians. Press brakes are essentially indented work benches above which are suspended movable pressing tools. The pressing tools are shaped to match the indentation in the workbench, so when a sheet of metal is positioned between the pressing tool and the working surface, the metal is pressed into the indentation, forcing it to take the indentation's shape.

A technician is generally required to manually position the metal and operate the pressing tool in this process. Other processes that involve moderate labor intensiveness are semi-automated robotic welding and mechanical punching processes.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

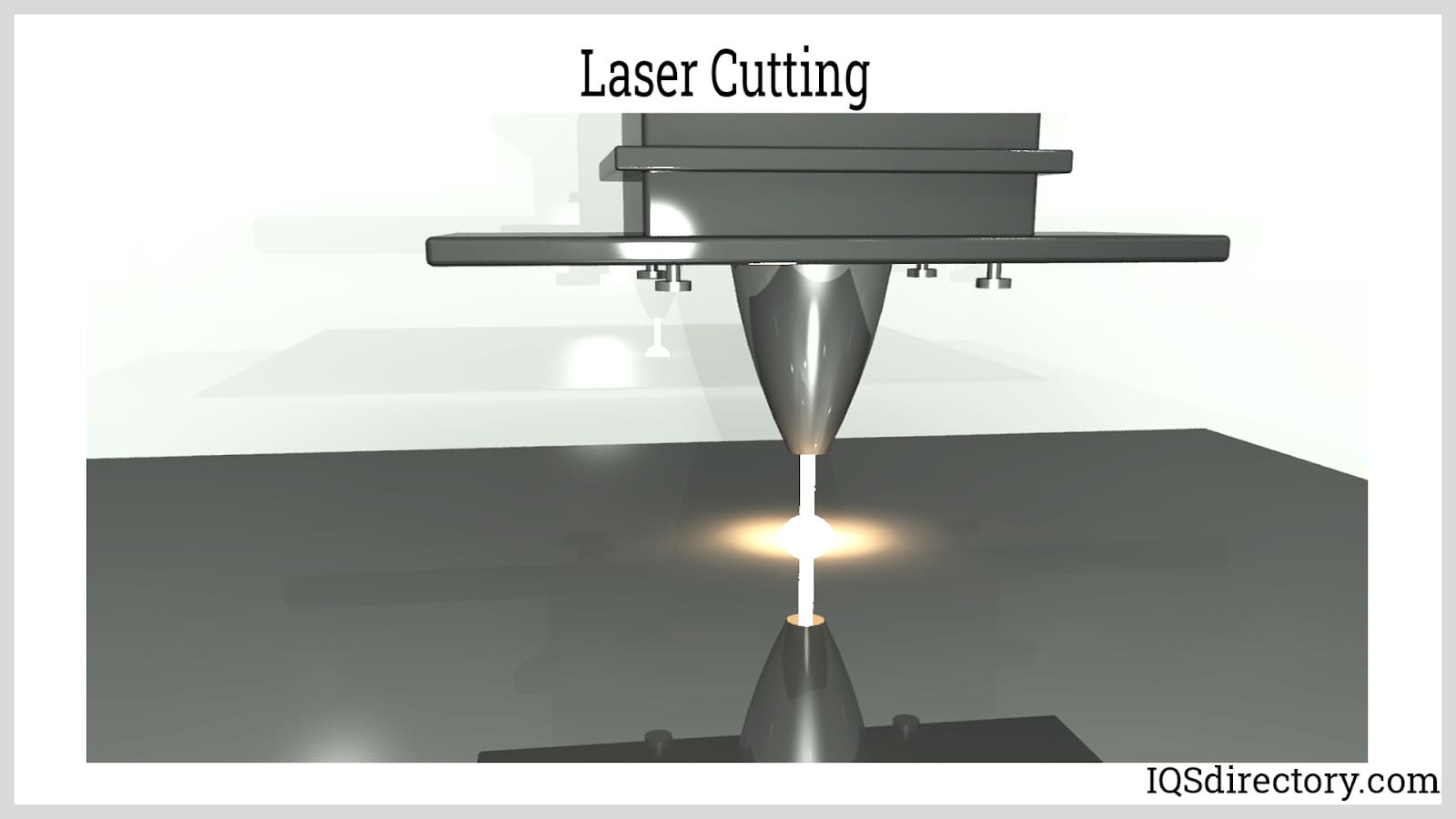

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services